Sustainable, smart and connected mobility in last mile systems

Strategic R+D+i Project MOSIC. (2021-2024)

The main objective of the project is the development of a system or set of vehicles that can work in coordination promoting Sustainable, Intelligent and Connected Mobility applied to the Last Mile. This proposal pursues the development of a Last Mile delivery system that combines the use of land vehicles and air vehicles, both being coordinated.

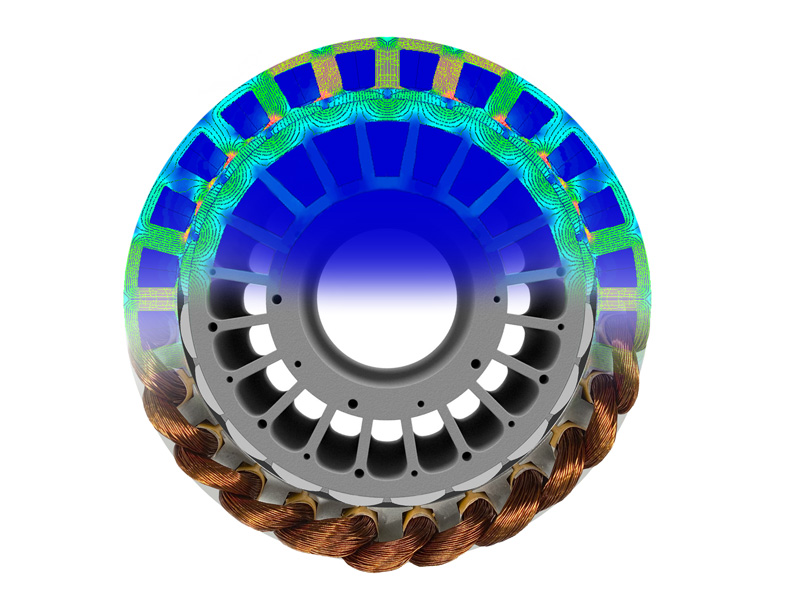

In Wheel motor

Strategic R+D+i Project VELETA (2019-2021)

Development of a prototype for an autonomous, connected and long-distance electric vehicle for the transport of people in private areas, such as airports, industries or hotels in which Permagsa has designed the in-wheel motor.

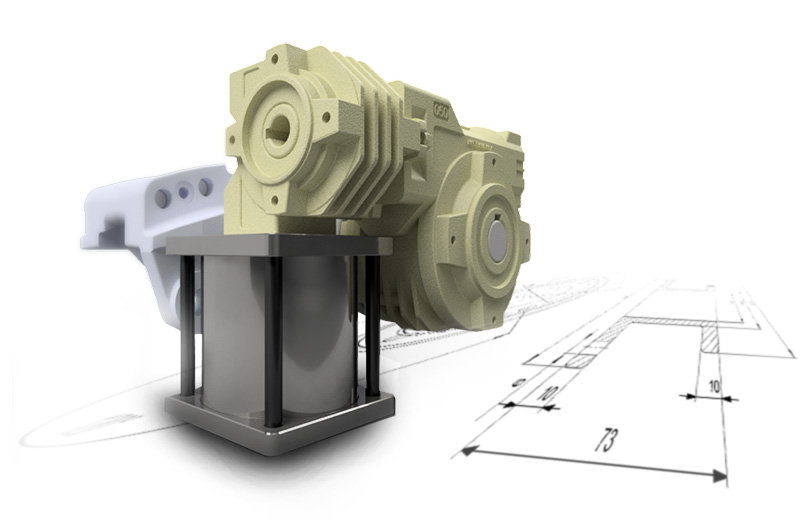

Electric Brake motor

Strategic R+D+i Project SOFIA (2018-2020)

Project to create a new generation of intelligent electric brake systems that improve behavior and functional performance, providing safety and comfort and enabling autonomous action. Specifically, PERMAGSA has developed new electric motors for the actuators of said brakes.

Electric Shock Absorber

Strategic R+D+i Project AEGEN (2018-2019)

The purpose of this project is the design and analysis of damping devices that are capable of generating electrical energy from vibrations in mechanical systems.

Motor for Electric Autonomous Micro-bus

Strategic R+D+i Project BOLETUS (2017-2019)

Development of a non-commercial prototype of a public transport vehicle (minibus) with electric propulsion with great autonomy. In this project, PERMAGSA has been in charge of the complete design of the water-cooled motor.

Hydroelectric Generator

Strategic R+D+i Project EHIERA (2017-2019)

Distributed storage based on hydraulic pumping for its application in micro-grids.

Motor for Dron

Strategic R+D+i Project MARVIN (2016-2018)

Development of the engine for a drone that obtains aerial images in civil naval applications as well as for fishing and maritime rescue.